05 Sep 2017

Posted by Dave under Dave's Thoughts,Geekstuff

The Big Finish

After 14 years, 5 months and 19 days I have finally completed the CNPS game that I started back in 2003! The realization, this past March, that I was close enough to finish the game in under a year gave me the push I needed to start paying closer attention to the game and actively look for plates. Once the weather got to be nice, I just made a point to go out for a walk at lunchtime almost every day.

After 14 years, 5 months and 19 days I have finally completed the CNPS game that I started back in 2003! The realization, this past March, that I was close enough to finish the game in under a year gave me the push I needed to start paying closer attention to the game and actively look for plates. Once the weather got to be nice, I just made a point to go out for a walk at lunchtime almost every day.

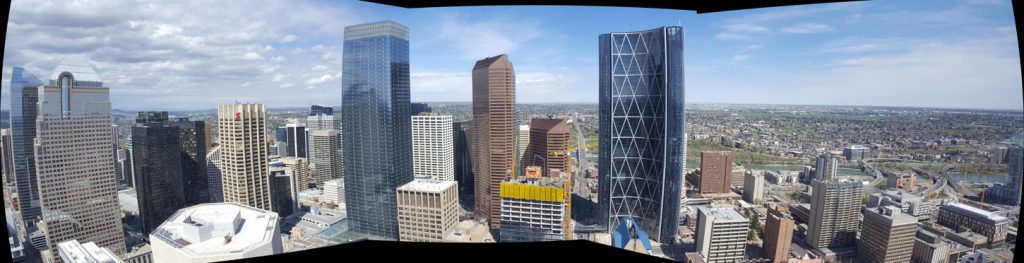

Working along 9th Avenue at the west end of Calgary’s downtown, was quite convenient as there are surface parking lots from 4th to 8th Street – loads of cars to walk by every day. With enough variation to constantly see new cars and enough stability to find numbers a second time when their turn came. … hey, don’t be giving me that look!

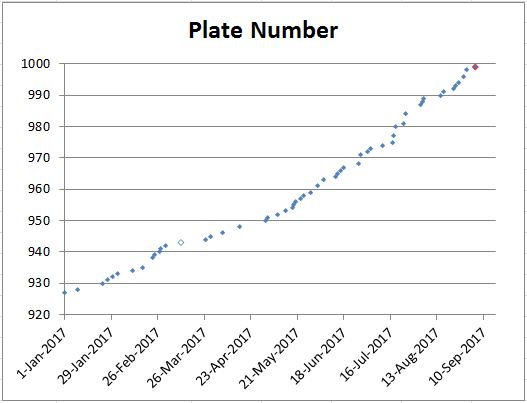

The graph above shows the progress since the start of 2017. The open circle data point is the where I was on 17 March, the 14 year mark. You can see how the 3 or 4 per month rate in the first quarter jumps up around the end of May going to a rate of about 12 per month over the summer. There were multiple occasions where I saw two or three plates in a single day. What a difference from when I was languishing in the 700’s at 45 plates per year.

Anyway, it’s a giant relief to have finished and I hope it doesn’t take too many weeks to train myself not to swivel around to see every car license plate that goes by!

Best of luck to Scott and Joel as they continue the Quest! Remember, it’s not crazy – it’s a calling.

Comments Off on The Big Finish